Manufacturing industries constantly have the challenge of needing to enhance productivity and efficiency, at the same time, they try to reduce downtime and keep the same quality. Smooth machine operation, process control at higher precision, and fast troubleshooting to the point of stopping production show the necessity of an Industrial Automation Services Provider.

SR Automation delivers reliable automation solutions designed for real shop-floor environments. By supporting existing machinery and operational constraints, performance is improved, operations remain stable, and long-term efficiency is achieved across manufacturing plants.

Understanding the Role of an Industrial Automation Services Provider

An industrial automation services provider supports manufacturing units by designing, implementing, and maintaining automation systems that control machines and processes. The mentioned services not only help in the continuity of the machine operation, but they also contribute to the excellent process control and coordinated working of different production stages.

Automation services go beyond installation. They include system planning, panel design, programming, testing, commissioning, and ongoing service support. . A dependable service provider will make a very good partnership with the production teams to gain insight into their needs and accordingly provide solutions that are suitable for the existing workflows, thus making changes less troublesome and not unnecessary.

Core Automation Services That Support Manufacturing Operations

PLC Programming and System Integration

Programmable Logic Controllers are the most important element of industrial control systems. Accurate and safe operation of processes is guaranteed through proper PLC programming. SR Automation’s services perfectly align with plant-specific requirements that include logic, safety, and production goals.

The connection of PLCs to various elements like sensors, drives, and operator interfaces is termed as system integration and this allows for the real-time monitor and control throughout the production line.

HMI Development and Operator Interface Design

Human Machine Interfaces make it a simple and quick process for operators to work with machines. An effective HMI increases the ease of visibility, decreases the number of operating errors, and thus aids in troubleshooting that is faster. Custom-made HMI screens are created in accordance with the actual plant operations to ensure that operators are able to confidently manage the equipment during daily production.

Clear alarms, simple navigation, and meaningful data presentation help manufacturing teams maintain control over complex systems.

Variable Frequency Drive Installation and Support

Motor control is a key area where automation services directly impact energy usage and machine performance. An experienced industrial automation services provider supports manufacturing plants with VFD selection, installation, parameter tuning, and troubleshooting.

Properly configured drives help achieve smooth motor operation, reduced mechanical stress, and optimized energy consumption. This directly contributes to improved machine life and lower operational costs.

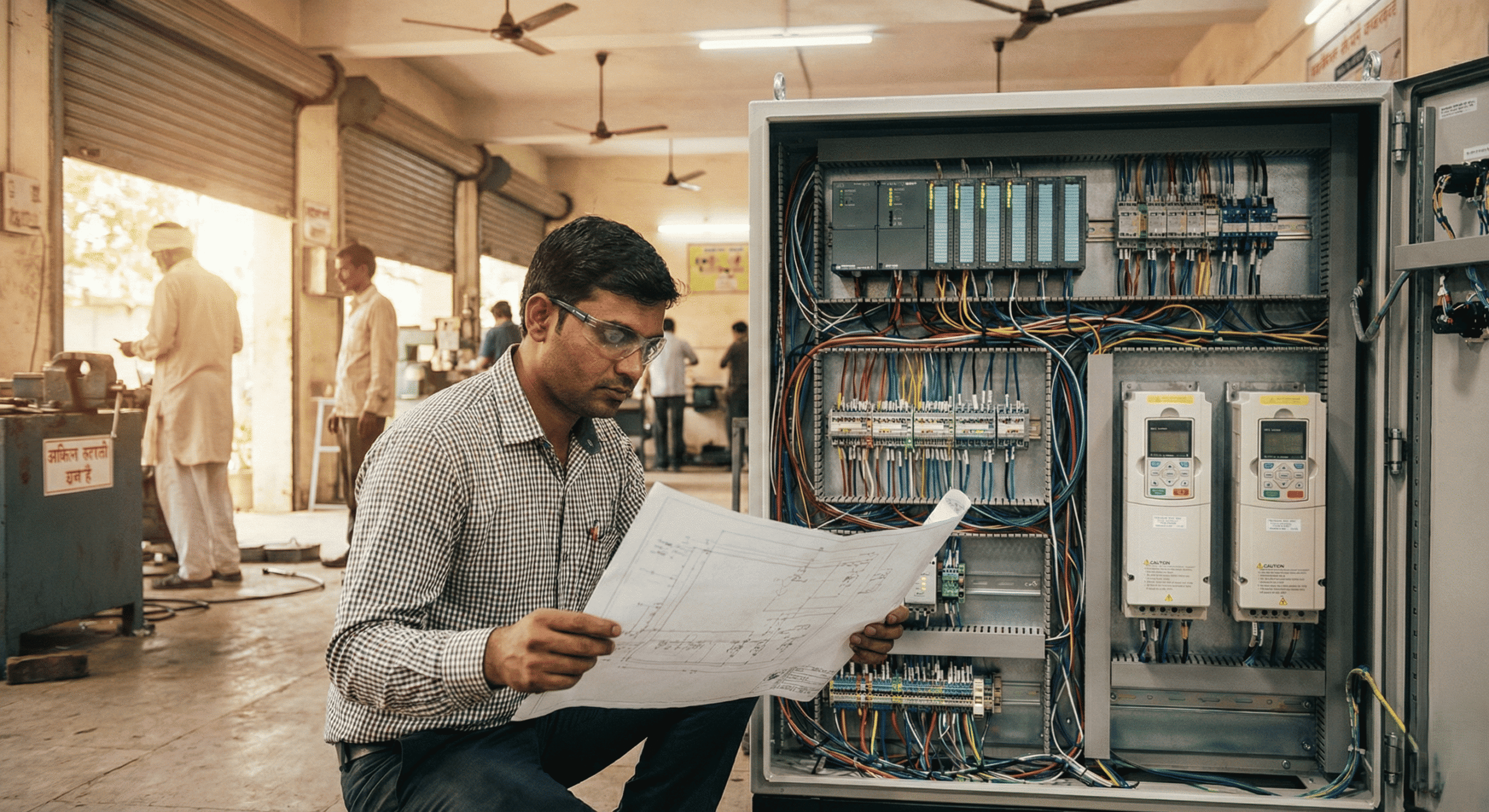

Control Panel Design and Modification

Control panels are the places where the most important automation components live and hence the planning of their layout must take into account safety, reliability, and maintenance access. The services related to the panels include new panel manufacturing, system upgrades, wiring modifications, and fault rectification.

Panels built and serviced according to industrial standards ensure stable operation and make future expansion easier for manufacturers.

Supporting Existing Machinery and Legacy Systems

- Many manufacturing plants run both modern and older machines, making full replacement costly and impractical.

- Industrial automation services providers upgrade existing systems to improve performance while preserving mechanical structures.

- The replacement of outdated PLCs, HMIs, and control panels with state-of-the-art systems results in a more stable and efficient operation.

- The modern VFDs have replaced the old or inefficient drives resulting in better energy efficiency and motion control.

- Control logic and software are modernized to improve reliability, safety, and system compatibility.

- Upgrades are executed with minimal production interruption to reduce downtime.

- Modernizing automation components extends the life of critical machines without major capital investment.

Industrial Automation Services Provider in Manufacturing Maintenance

Preventive and Breakdown Support

Unscheduled interruptions can greatly affect the output and also lead to postponements. The personnel of the automation service teams dedicate their efforts to preventive maintenance and prompt troubleshooting so that the machines will not have any problems operating.

Early Problem Detection

Detecting the problems at the very beginning of their development helps in the prevention of the unexpected stoppage. It makes the plant more stable and cuts down on the need for emergency repairs.

Skilled Service Engineers

Experienced engineers work alongside maintenance teams to resolve problems fast and safely, understanding the urgency of production schedules.

Process Optimization

The automation services have a look at the machinery, its operation, and control logic to spot the points where the processes can be made to run more efficiently.

Efficiency Improvements

In most cases, the small changes done to the timing, sequencing, or control settings can lead to an increase in productivity and quality while at the same time the entire existing automation system will be utilized to the fullest.

Why Manufacturing Units Choose Local Automation Service Providers

- Manufacturers prefer a local industrial automation services provider for faster response times.

- Local providers have a better understanding of regional industrial practices.

- On-site assistance permits faster visits and better communication.

- A local provider makes it easier to control reliable after-service support.

SR Automation is providing practical service to the industries in Coimbatore and its surrounding areas.The company provides on-site repair and permanent technical support. Services are adapted to the precise requirements of local manufacturing operations.

Industry Applications Supported by Automation Services

Textile and Garment Manufacturing:

Automation guarantees that the cutting, sewing, and weaving processes remain exact and efficient. Through machine maintenance, fabric quality is also made sure to stay constant.

Packaging and Material Handling:

The entire process of conveyors, robotic arms, and packaging equipment is automated in order to achieve a quicker and more precise output. The focus of the services is to keep the production lines running non-stop.

Foundry and Metal Processing:

Automation brings about the enhancement of safety and precision in metal casting, machining, and handling. The combination of timely upgrades and monitoring is a waste-reduction strategy that doubles the efficiency.

Food and Beverage Production:

The processing and packaging lines undergo automation to gain the ability to maintain, at the same time, hygiene, speed, and the quality which is consistent. The preventive service is the one that keeps the operations running smoothly and prevents any downtimes.

Automotive Component Manufacturing:

The assembly lines and robots are kept in good working order to guarantee high-volume production and precision output. Upgrades, in addition to regular checks, are the power behind efficiency maximization and safety.

Custom Adaptation:

The automation services are tailored to the requirements of each sector, thus guaranteeing reliable performance and compliance with standards.

How an Industrial Automation Services Provider Adds Long-Term Value

The value of automation services is not limited to quality of installation only but long-term system reliability is another major factor. A responsible service provider documents system logic, provides operator guidance, and supports future expansion.

Stable systems, predictable performance and reduced doubts regarding the automation infrastructure are the main gains for manufacturers. This partnership approach of trust will last through time and will also result in smooth operations.

Choosing the Right Industrial Automation Services Provider

Practical Industry Experience: Select a collaborator possessing practical knowledge from real manufacturing settings.

Support for Existing Systems: The supplier should be capable of working together with your current machinery and automation systems.

Responsiveness During Breakdowns: Quick reaction time is really important for minimizing the effect of unplanned stops.

Clear Communication and Documentation: Constant communication and precise documentation are the conditions necessary for a successful partnership.

Commitment to Long-Term Support: A reliable partner always brings technical support and assistance.

Service-Oriented Mindset: Uninterrupted production relies on a provider that continually gives priority to customer requirements and system availability.

Reliable Automation Support for Manufacturers

If your manufacturing unit requires dependable automation support, SR Automation offers practical and Industrial Automation Services Provider solutions tailored to real production environments. From PLC programming and VFD services to control panel support and system upgrades, our team works closely with manufacturers to ensure smooth and efficient operations.

👉 Visit: https://srautomation.org/services/👉 Contact SR Automation to discuss your automation service requirements and improve the reliability of your manufacturing operations.