Industrial machines are required to operate in a safe, precise, and continuous manner. To achieve this, manufacturing plants resort to the application of automation systems that take over the control of machines. PLC programming for industrial automation is one of the major technologies that guarantee the correct execution of the machine’s instructions and tasks.

SR Automation, we aim at the development of automation technology that is not only simple but also reliable and convenient. Our setups are user-friendly, low-maintenance, and suitable for working in daily industrial operations.

What Is PLC Programming and Why It Is Important

PLC stands for Programmable Logic Controller(PLC), is a special type of computer used in industries to control machines and processes. It gives the engineers the power to create the instructions for the machines, like when to start, stop, move, or respond to a signal. This method called PLC programming for industrial automation guarantees the machines to perform the tasks with precision and reliability with no human supervision at all.

PLCs are different from normal computers because they are built to work in harsh industrial environments. They can tolerate the factors such as heat, dust, and vibrations and their operation can be continuous for long hours. This very quality makes them fit for areas such as factories, warehouses, and production plants where machines are needed to run continuously and failure is not an option.

The factories can benefit a lot from the optimizations that come along with using PLC programming like the elimination of repetitive tasks, increased efficiency, and even the retaining of quality. It also helps minimize human mistakes and adapt the machines more easily to the changing production needs. The industries with PLCs can have smoother operations while keeping machines safe and reliable.

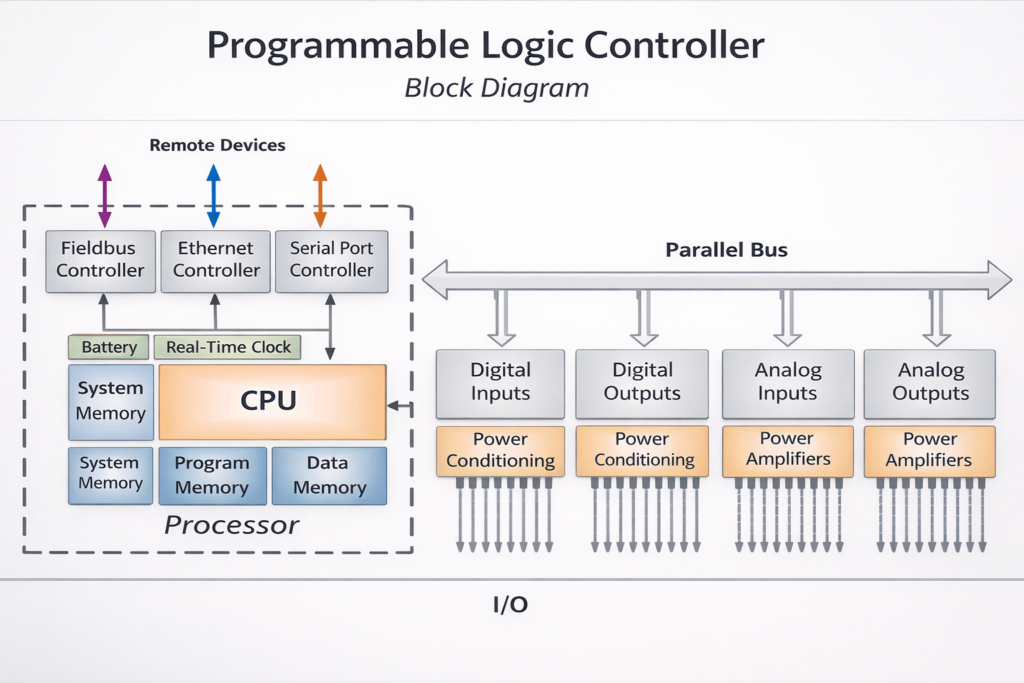

How PLC Programming for Industrial Automation Works – PLC Block diagram

In simple terms, PLC programming works by reading input signals and giving output commands. The input modules are where the PLC receives signals that come from sensors and switches. The CPU of the PLC takes care of the processing of the signals according to the logic that has been programmed and stored in the memory. The PLC, using the defined conditions in the program, sends the output commands to control the motors, valves, relays, or any other industrial devices.

PLC programming allows the whole process to work in real-time, with high reliability and maximum safety, that too in extreme environments where the machines are operating.

PLC Programming for Industrial Automation in Daily Factories Operations

Factories use automation to reduce manual work and improve accuracy. plc programming allows machines to perform repeated tasks with the same quality every time.

This helps industries:

- Reduce human errors

- Increase production speed

- Maintain consistent product quality

- Improve worker safety

With proper PLC logic, machines work together as one complete system.

Why Custom PLC Programming Is Better Than Standard Programs

Every factory is different. Machines, processes, and production goals vary from one industry to another. plc programming for industrial automation should always be designed based on actual requirements, not copied from another system.

Custom PLC programs:

- Match real production needs

- Reduce unnecessary machine movements

- Make future changes easier

- Improve system reliability

SR Automation creates solutions that fit your exact process.

PLC Programming for Industrial Automation and Machine Safety

Safety is a major concern in any industrial environment. Machines must stop immediately during emergencies. plc programming for industrial automation includes safety logic such as emergency stops, safety sensors, and interlock systems.

This protects:

- Operators

- Maintenance staff

- Machinery

- Production materials

Good safety programming prevents accidents and reduces downtime.

Why Choose SR Automation for PLC Programming

Practical Solutions That Work on the Shop Floor

SR Automation focuses on PLC solutions that work well in real factory conditions. Our programs are built to run smoothly during daily production without causing delays or breakdowns.

Reliable Control You Can Trust

PLC programming for industrial automation at SR Automation is designed to be stable and dependable. We make sure machines respond correctly to signals and operate safely at all times.

Simple Programs for Easy Maintenance

The PLC programs we write are very clear and easy to read. In this way, the maintenance staff can very quickly locate the problems and do the necessary changes without stopping production for a long time.

Flexible Designs That Grow with Your Needs

Our PLC systems are built in such a way that they will be able to cope with changes in the future. There is no need to rewrite the whole control program to add new machines or process updates.

Working Closely with Our Clients

SR Automation works closely with customers to understand their machines and production goals. This helps us deliver solutions that fit their process and improve overall efficiency.

📞 Ready to automate your operations? Call 99656 31182 and connect with SR Automation today.

Role of PLC Programming in Process Automation

Process industries such as chemical, food, and water treatment plants rely heavily on automation. plc programming for industrial automation controls temperature, pressure, flow, and timing with high accuracy.

To ensure the best quality and really work in accordance with industry standards and adopted regulations, automated controls can guarantee product quality.

PLC Programming for Industrial Automation with HMI and SCADA

Operators need to see machine status and control processes easily. plc programming connects PLCs with HMI and SCADA systems for monitoring and control.

These systems allow operators to:

- View machine status

- Detect faults quickly

- Control machines from one location

- Record production data

Clear displays improve productivity and reduce errors.

Common Industries Using PLC Automation

Many industries depend on PLC-based systems. They are widely used in:

- Manufacturing plants

- Packaging units

- Material handling systems

- Food and beverage industries

- Pharmaceutical industries

Each industry has different needs, and PLC logic is adapted accordingly.

Importance of Proper PLC Program Structure

A well-designed PLC program can be very easily understood and maintained. The PLC industrial automation programming is based on structured methods so that the technicians may troubleshoot the problems quickly.

Good structure helps:

- Reduce maintenance time

- Avoid long downtime

- Make upgrades easier

- Improve system life

Clear logic saves time and money.

Maintenance and Troubleshooting Using PLC Logic

Machines can encounter difficulties because of wear, power issues, or malfunctions in the sensors. The use of plc programming assists in locating the problems through alarms and fault messages.

This allows maintenance teams to fix issues faster without stopping the entire production line.

PLC Programming for Industrial Automation and Energy Efficiency / Consumed

It is the efficient machines that consume less power. PLC programming for automation in industries is a way to manage the operation of motors, drives, and other devices just when it is actually needed.

This results in:

- Reduced electricity costs

- Less stressed equipment

- No unnecessary machine operability

Energy-efficient automation is a win-win scenario for both the enterprise and nature.

Future of Industrial Automation with PLC Systems

The process of automation is gradually paving a way for smart factories and digital systems. PLC programming for industrial automation is the starting point for the advanced technologies such as data analysis and predictive maintenance, which will be widely used in the future.

Modern PLC systems allow communication with cloud platforms and industrial networks, thus making it easy to upgrade in the future.

Get Expert Automation Support Today

If you are planning a new automation system or want to improve an existing one, professional PLC programming is essential. plc programming for industrial automation helps your business operate smoothly, safely, and efficiently.

Visit SR Automation or contact our team to discuss your automation needs and get reliable PLC programming services tailored to your industry.